It's been a little while since I last wrote a blog, but unfortunately any spare time lately has been spent trying to move the project a little further on. I think last time I had just started looking at Autodesk Eagle and found it to be quite un-intuitive but managed to glean enough from the internet to get moving.

So eagle is a program which does a couple of things (that I've discovered so far). The first use is for designing nice legible electronic schematics, using real life components that can be pulled from an internal library - which can be expanded via the internet to pretty much anything you can buy, and that which you can't can be created by hand. It's pretty easy to use once you've understood the basics and took me right back to my school electronics classes with resistors and LEDs, kind of fun even!

So eagle is a program which does a couple of things (that I've discovered so far). The first use is for designing nice legible electronic schematics, using real life components that can be pulled from an internal library - which can be expanded via the internet to pretty much anything you can buy, and that which you can't can be created by hand. It's pretty easy to use once you've understood the basics and took me right back to my school electronics classes with resistors and LEDs, kind of fun even!

My first problem came when I realised that the servo motor I wanted to use was not available anywhere online - in fact the units themselves seem to only be available direct from the Chinese manufacturer via Alibaba so I'm not really surprised - they're pretty much unique to the automotive instrument industry it seems. So I had to make the Eagle model myself which took a bit of time, as not only do you have to draw the unit in 1:1 scale, but also carefully place and label the contact points and then assign those contact points to the model.The reason for this is is the second use for Eagle - designing PCBs!

|

| Eagle Schematics - Really Enjoyed This Bit! |

Once you've made your schematic, then you flip the view into PCB building mode, and all of your components appear on a blackboard for you to arrange as you see fit on the front or back of the board. Every contact point that is connected on the schematic is joined by a very thin direct line forming a kind of web on the blackboard - these are the fixed connections you've made on the schematic, so that once you've arranged the components how you want them, Eagle can perform its party piece; routing the copper traces between them all. This is a super satisfying and really impressive process where the computer in real time in front of your eyes begins to lay out each connection across either side of the board like tree roots. Since these wires need to avoid each other to prevent a short circuit, the computer chooses either to drop through the board using a "via" (a hole from one surface to the other) or to simply route around the problem in the most efficient manner. Over a couple of minutes it gradually refines its routes until you have something that looks like a real circuit board - truly amazing.

|

First shoots... |

|

| Getting there... |

|

| A circuit board! |

So I set about designing my board to hold the stepper motors and the Arduinos to power them, and before long had something that looked like a reasonable starting point. I then scratched my head wondering how on earth I would make it the right shape when the housing was being designed in another program. Thankfully, Eagle allows you to export the board as a .step 3d file which can be imported into Inventor (my 3D package of choice) and thus manipulated into the main assembly.

My first attempt taught me that I probably needed to start by sketching the outline of my board in Inventor to fit it into the space that I had available in the housing, before exporting the outline file as a .dxf cad drawing file to import as a drawing layer in Eagle. This is a bit long winded but it then gave me the exact space that I had available to then try and fit my components into. After a bit (a lot) of trial and error, I got a bit of a process together, iterating towards my goal.

|

| An early mockup of the shell and circuit board |

The next issue was that in order to get the shafts of the two smaller gauges as close together as possible, I needed to stagger the stepper motors one on top of the other, which meant one of them needed to sit on a different PCB 6mm above the other. A second board was born, and onto this one I added the ribbon cable sockets to then plug the cluster into the outside world.

With the front and back PCBs beginning to take form, I started on the challenges of how to suspend the boards securely within the housing, while not interfering with the backlights that hadn't yet been designed - these would need to sit as far back in the housing as possible to diffuse the light evenly around the gauge, and of course this meant not putting any PCBs in the way. With the makings of a plan, I started to refine the actual design of the gauge decal (the printed bit on the front) as it would influence the PCB design.

While looking for components to use in Eagle, I also had more of a look around for the harder to source components to make sure that could actually get hold of them; if I couldn't then it was starting to have implications of big about turns on the design. The stepper motors VID-023 seemed to be impossible to acquire beyond the couple that I already had, and it turned out after some research with suppliers that they had been discontinued, though thankfully there was a replacement model, the BKA30L-F1 - what a name!

|

| Drawing pointers |

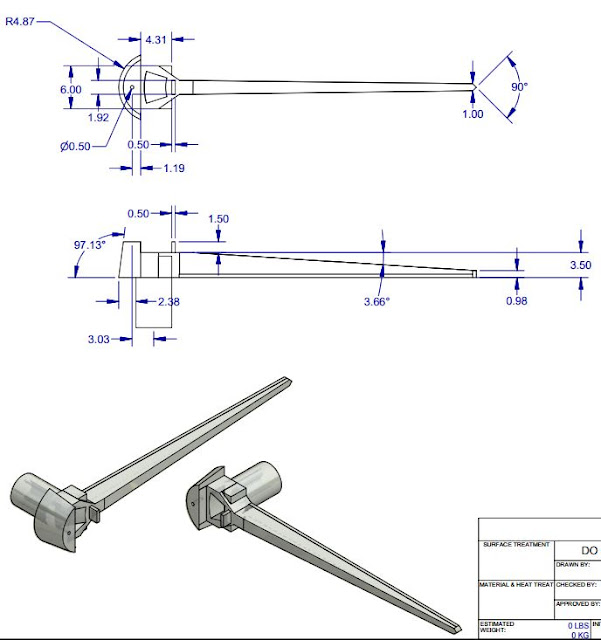

The next hardest thing to find was the pointers. I had a couple of quite nice looking ones, but the shorter ones to use on the smaller gauges seems to have hubs that looked much too big and out of proportion to the rest of the unit. I scoured Alibaba and Ebay for alternatives and found nothing but cheap looking orange ones in their thousands which would look rubbish., so I decided to look at making my own using the ones I had as a reference.

Taking the ones I had apart revealed that they are made of a couple of bits; a clear plastic part which has both the main hub which pushes over the stepper shaft to hold it in place but also transmit light through from the stepper up to a reflector (45 degree flat surface) which sent the light down through the pointer to be reflected off the paint on the underside. Around that, to prevent light escaping around the hub was a small black plastic hub cap, and on the larger pointer a small retaining ring to both hold on the cap and stop light escaping around the bottom of the hub. I modeled them up in 3D to play with the design and make up some engineering drawings which I sent to a few UK manufactures to see if they could be injection molded.

They could at a unit price of around 10p per part, but the tooling was going to cost around £5000 to CNC machine - ouch! There was a nice lesson in why we don't injection mold small volume parts...! So how else to make them. Of course there is 3D printing, which is high enough resolution these days to get a decent surface finish on the black parts, but the clear parts, not so much. 3D printing introduces air bubbles, dust and all kinds of impurities which render the part difficult to pass light through so they appear cloudy at best. Speaking with an immensely helpful Gretchen from ProtoLabs, it seemed that stereo-lithography might be the answer. This is essentially 3D printing except the part is etched using a pair of lasers in a bath of liquid plastic, with the part rising out like the Terminator. Awesome. The optical qualities of parts made in this was is almost perfect, and the per unit price was just a few pounds so much more like it for my application. After sending ProtoLabs my 3D models to review, they made some minor comments to improve printability which I included so they're now ready to go when needed. Doing it this way allows me not only to make them look exactly as I want them, but also to extend the hub length of the pointer sitting on the offset stepper which should neatly solve that problem too.

Comments

Post a Comment